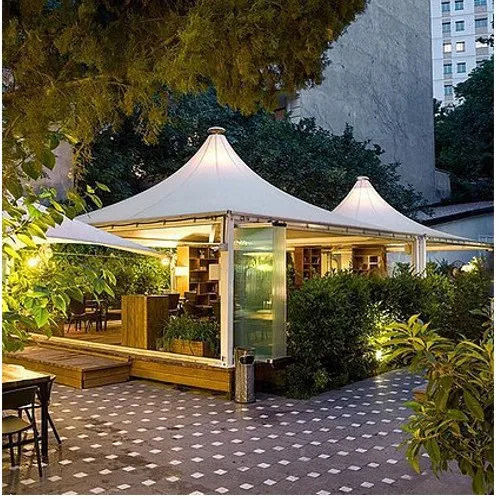

Conical Tensile Structure

Product Details:

Conical Tensile Structure Price And Quantity

- 2000 Square Foot

- 350.00 - 2250.00 INR/Square Foot

- 350 INR/Square Foot

Product Description

Scope of Work

The scope of work includes:

Design, engineering, and detailing of the tensile structure.

Selection of materials for the membrane, cables, supports, and anchors.

Fabrication of all structural components, including tensioning systems and support frames.

Installation and tensioning of the fabric and supporting components on-site.

Design Requirements

Form and Shape: The conical tensile structure shall have a conical or hyperbolic shape, with a central apex and radially symmetrical design. The geometry should be designed to provide both aesthetic appeal and structural stability.

Tensioning System: The structure shall be equipped with an efficient tensioning system, which may include cable netting, steel cables, and turnbuckles. This system should allow for precise adjustment of the membrane's tension to maintain the desired form and stability.

Materials

Membrane Material:

The membrane shall be made of high-performance tensile fabric material with UV resistance, Fire Resistance, tear resistance, and water resistance. Common materials include PVC-coated polyester, PTFE (polytetrafluoroethylene).

The fabric must be durable and resistant to extreme weather conditions (e.g., UV degradation, temperature fluctuations, and pollution).

The fabric should also meet fire-resistance standards in accordance with local building codes.

Structural Supports and Cable System:

Cables: High-strength steel cables or carbon fiber cables should be used for load transfer and tensioning, with a corrosion-resistant coating (e.g., galvanized or stainless steel).

Frame Structure: The support frame may be made of steel or aluminum, designed to withstand both static and dynamic loads. The frame must be Painted, powder-coated or galvanized for long-term durability.

Installation

Site Preparation: The installation site should be prepared to accommodate the foundations, anchors, and any associated utilities.

Structural Assembly: The installation process will involve the assembly of the frame and support structure, followed by the mounting of the tensioned fabric.

Tensioning: Once the fabric is mounted, the tensioning system must be carefully adjusted to ensure uniform tension across the membrane, with particular attention to maintaining the structural geometry and load distribution.

Maintenance and Warranty

Maintenance Guidelines: Regular inspection and maintenance should be scheduled every 12 months to ensure the integrity of the structure. This includes checking for fabric wear, cable tension, and anchor stability.

Warranty: 5-year warranty should be provided on the PVC Coated Tensile Fabric, covering defects in materials or workmanship. Extended warranties can be considered based on the terms agreed upon during the contract phase.

Compliance and Standards

The design and construction of the conical tensile structure must comply with relevant building codes, safety regulations, and local zoning requirements, including:

ISO 13934-1: Testing of fabric for tensile strength.

ASTM E84: Fire tests for building materials.

Local building codes regarding wind load, snow load, and structural safety.

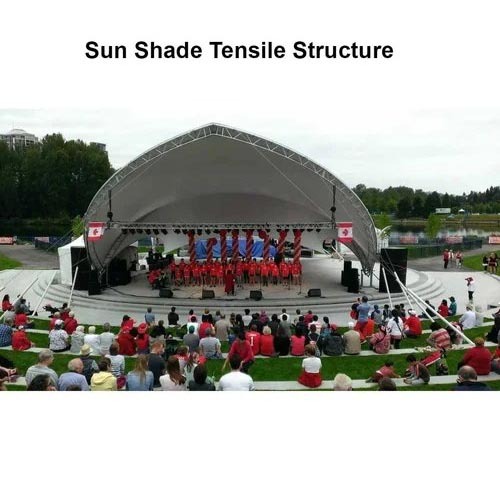

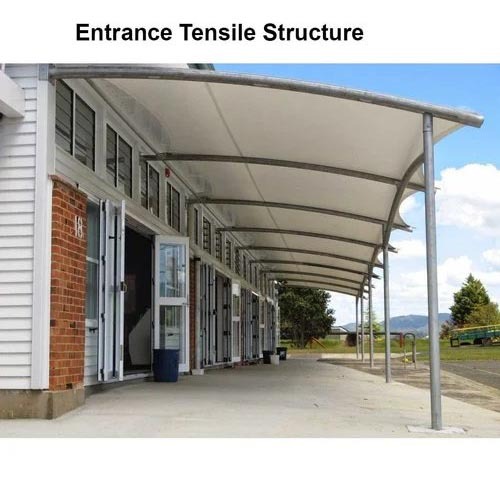

Other Products in 'Tensile Structures' category

|

ASHA INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS